Analysis and test center

Our analysis and test center serves the consumer electronic terminal and components industry, memory and storage products industry, semiconductor chip industry, medical device industry and intelligent measurement industry. Focus on material analysis and testing, SMT defect diagnosis and solutions, production process control data collection and analysis, production process innovation and improvement, product reliability testing and evaluation. In ESD static control, micro pollution control and clean production overall solution, mechanical vibration and resonance test analysis, stress and strain test analysis, SMT defect diagnosis and other fields in the industry's top level.

◆ Material analysis

◆ Failure analysis

◆ Reliability engineering

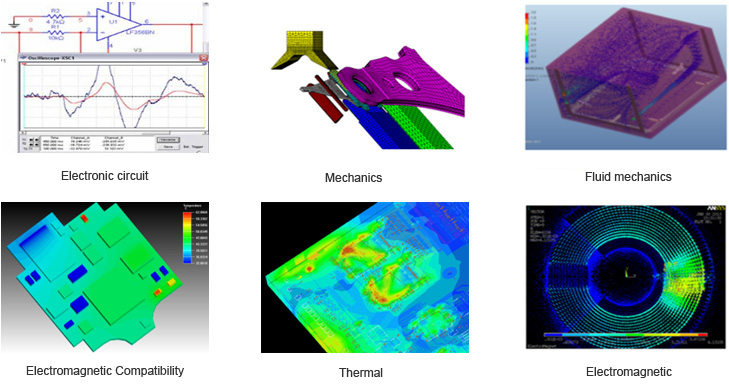

◆ Simulation

Material analysis

Approved by China National Accreditation Service for conformity assessment (CNAs), it has the following material analysis technical capabilities:

◆ Characterization of Q surface morphology and structure and analysis of material composition

◆ Analysis and identification of organic and inorganic micro pollutants and detection of RoHS / reach and other toxic and harmful substances

◆ Determination of physical and chemical indexes and heavy metals in wastewater sludge

◆ Electronic products cleanliness test drinking water index test

◆ Air quality inspection

◆ Testing and certification of mechanical parameters of materials

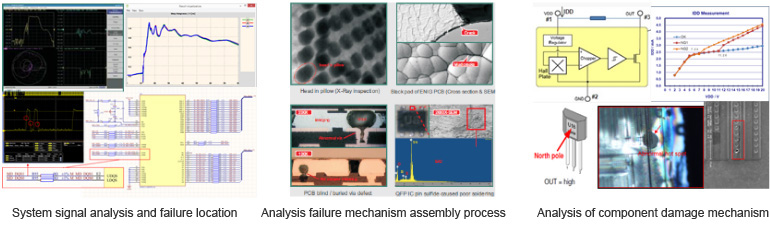

Failure analysis

Failure analysis is one of the important means to improve product quality and reliability. Have a complete ability to recognize the failure mechanism of the weak link of the product, in-depth, multi-dimensional, covering the failure physical process including mechanical, electronic, thermal, material and chemical, etc

◆ System level failure location

◆ Failure mechanism analysis of q-assembly process

◆ Failure mechanism analysis of Q components

◆ Failure analysis of Q material

Reliability engineering

Reliability design (DFR)

◆ Stage - concept and objective: determined by QFD / CTQ and other tools

Ÿ Product design scheme and objectives

Ÿ Reliability objectives, thermal, EMC, structural and Safety specifications

◆ tage - definition and analysis: establishment and implementation of reliability block diagram / reliability allocation / DFMEA / fraca and other tools and methods

Ÿ Reliability model

Ÿ Reliability prediction

Ÿ Reliability analysis of subsystem / part

Ÿ Reliability outline design

Ÿ Preliminary DFMEA and fracas plan

◆ Stage - optimization design and test: using the methods of robust / ALT / halt / DFMEA / fracas

Ÿ Optimization design, thermal mechanical stress analysis

Ÿ Reliability test plan and mechanical, electromagnetic compatibility and safety test plan

Ÿ Update DFMEA and implement fracas

◆ Phase - Verification and evaluation

Ÿ Complete reliability verification and evaluation, mechanical / electromagnetic compatibility / safety test report

Ÿ Update DFMEA

Ÿ Fracas Report

◆ MP phase mass production reliability test

Ÿ Ort test scheme

Ÿ Reliability sampling test scheme

Reliability engineering services

◆ Reliability test scheme and data analysis

Ÿ Design of test parameters for standard guidance

Ÿ Environment, EMC safety regulation and durability test

Ÿ Data analysis

◆ Reliability life index verification

Ÿ MTBF prediction

Ÿ MTBF qualification test design

Ÿ Product life assessment and verification

◆ Product design validation

Ÿ Product design verification scheme customization

Ÿ Improvement suggestions and reliability growth

◆ Manufacturing reliability analysis and evaluation

Ÿ Design of process reliability appraisal scheme

Ÿ Quality inspection, reliability evaluation and improvement of welding interconnection

Ÿ Analysis and improvement of mechanical reliability

◆ Reliability consulting and training

Ÿ Process reliability technology

Ÿ Type selection and reliability analysis of semiconductor devices

Ÿ EMC design and improvement

◆ EMC design and improvement

Ÿ EMC solution design

Ÿ Rectification of EMC testing problems

Ÿ EMC pre certification service

Analogue simulation

ANSYS multi physical field

◆ Analysis of q-structure, heat, fluid, electromagnetic and coupling fields

◆ Parametric modeling, design optimization

ICEPAK

◆ Thermal management of Q electronic products

◆ Radiator design, fan, runner layout

MATLAB

◆ Engineering calculation

◆ System modeling