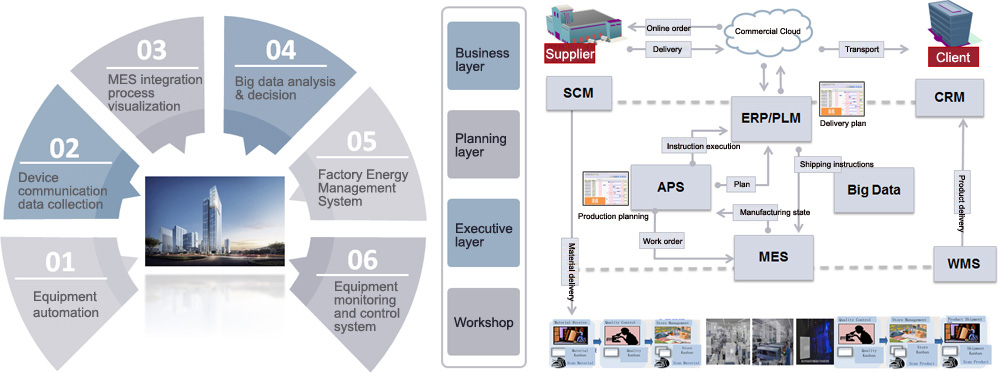

Intelligent Manufacturing

Solution of intelligent manufacturing system

We focus on "made in China 2025", realize intelligent production and intelligent analysis through independent research and development of intelligent manufacturing system, and build an intelligent manufacturing factory with high efficiency, flexibility, intelligence and high integration

Generic Technology

Generic technology refers to all kinds of technologies that have been or may be widely used in many fields and have great economic and social benefits for the whole industry or industrial technology level, industrial quality and production efficiency. We provide the following generic technology solutions in the electronic manufacturing industry:

◆ anti static technology and solution

◆ clean production technology and Solutions

◆ aseptic production technology and solution

◆ stress and strain management and Solutions

◆ vibration control and management

◆ polishing technology with high efficiency

◆ welding technology and assembly technology

Anti static solution

ESD (electrostatic discharge) affects the productivity, quality and reliability of electronic products from all aspects, and is regarded as the biggest enemy in the electronic manufacturing industry. We have nearly 30 years of technology accumulation in the field of anti-static, and are also the makers of many technical standards in this field, with a number of patented technologies. Available:

◆ESD system construction: provide overall ESD system construction scheme and implementation scheme according to ANSI / ESD s20.20 requirements

◆ intelligent ESD protection system and products:

Ÿ intelligent ESD monitoring system

Ÿ intelligent ion fan

Clean production environment solution

To provide one-stop service of comprehensive design, optimization scheme, test and evaluation of clean room. We have accumulated nearly 30 years in the field of clean room technology, and we are also the maker of many technical standards in this field, with a number of patented technologies.

◆ Selection and evaluation of Q fabrics and styles

◆ clothing cleaning equipment, cleaning process design and evaluation

◆ Performance evaluation of Q cleanliness and ESD

Aseptic production environment solution

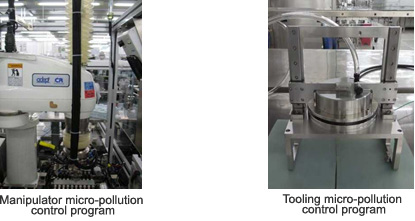

Micro pollution control technology in clean production

Provide clean product production cleanliness control program, pollution source identification and prevention of technical solutions. The relevant scheme has won the science and technology progress award of China Electronics and China Electronics Society, and has the patent of "detection technology of micro particle pollutants on product surface".

◆ Cooling pollution design and optimization of Q process flow and production line layout

◆ Control and reduction of micro particulate pollutants in equipment and tooling

◆ Identification and control of Q organic inorganic particulate pollutants

Aseptic production control solution

Have aseptic control system technical solutions for medical products production, and provide technical services:

◆ CFDA, FDA certification services

◆ Design, evaluation and approval of Q aseptic clean workshop

◆ Formulation and validation of Q sterilization process

◆ Sterility testing and monitoring of production environment and products

Precision cleaning technology

With precision cleaning technology (DI water cleaning technology, solvent cleaning technology and ultrasonic cleaning technology, etc.), we provide precision cleaning technology solutions for materials, packaging boxes and process boxes, semi-finished products or finished products, etc. the relevant solutions have won the science and technology progress award of China Electronics and China Electronics Society, and are the national standard setter for cleanliness of hard disk magnetic head products.

Application technology of electronic adhesive

Adhesive and bonding technology are the key technologies in the electronic manufacturing process, which can provide the following overall solutions of bonding technology.

◆ bonding process, parameter evaluation and optimization

◆ curing equipment, curing parameters, process evaluation and optimization

◆ bond strength and reliability evaluation

◆ Selection and application evaluation of Q adhesive

◆ Research on failure mechanism of q-bonding and Solutions

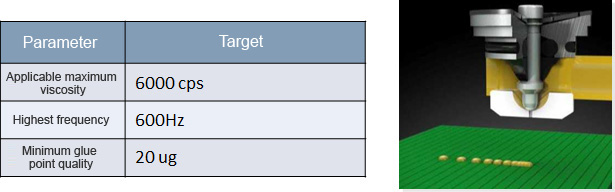

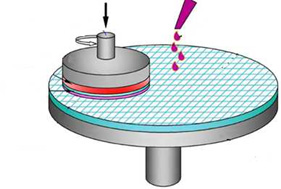

High speed spray dispensing technology

The miniaturization of electronic products requires smaller linewidth, higher speed and higher precision. High speed piezoelectric jet dispensing can meet this requirement. We provide piezoelectric high-speed dispensing solutions, suitable for high-speed and high-precision dispensing requirements of various viscosities, and provide supporting technical solutions for DFM and process design of your products.

High efficiency grinding

With efficient grinding and polishing technology and corresponding production scheme for a variety of materials, we can provide grinding and polishing technical scheme and OEM service for shell materials of consumer products, such as ceramics, sapphire, glass and other inorganic non-metallic materials, as well as various metal materials.

Welding technology solutions

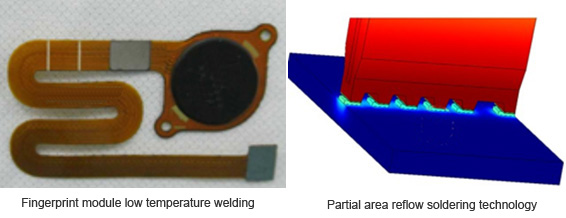

With complete PCBA level assembly and manufacturing capabilities, we provide technical services for many well-known enterprises at home and abroad. Technical solutions are available for the following special welding applications:

◆ low temperature welding technology: provides a solution for the welding and assembly of thermal sensitive components, module IC, led and components prone to thermal warping

◆ local area reflow soldering technology: realize the local soldering of small area, high speed, good reliability, can provide a complete set of technical solutions, has been widely used in hard disk components

Stress strain management

In the production process of PCBA, excessive stress caused by poor process may lead to ball cracking, component damage, pad warping and other problems. We can provide the technical scheme of over stress control in the manufacturing process.

◆ Risk investigation of overstress in Q process

◆ Force analysis of mechanical solder joint of q pair products

◆ Q stress management and optimization

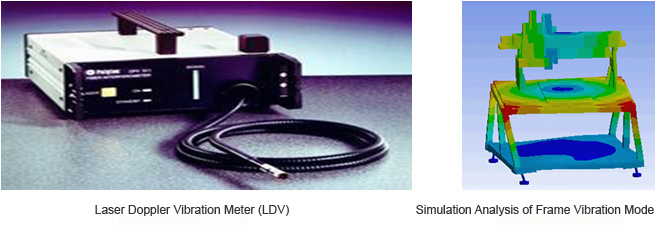

Structural vibration test and resonance mode identification

Dynamic / vibration performance is an important basic index affecting product design. We can provide a variety of experimental methods and theoretical simulation analysis related to structural vibration and resonance mode identification.